ER316LSi SS MIG WIRE | FEATURES

- ER316LSi is the same as ER316L, except for the higher silicon content.

- It improves the usability of the filler metal in the gas metal arc welding process.

- If the dilution by the base metal produces a low ferrite or fully austenitic weld, the crack sensitivity is somewhat higher than that of a lower silicon content weld metal.

- Welding process of ER316LSi SS MIG wire applied to MIG(Metal Inert Gas Welding) or GMAW(Gas Metal Arc Welding).

SPECIFICATION CONFORMANCES

AWS: A5.9/A5.9M: ER316LSi

UNS Number: S31688

BS EN ISO 14343A: 19 12 3 L Si

SHIELDING GAS

Short Circuiting Transfer: 90% He / 7.5% Argon / 2.5% CO2

Axial Spray Transfer: 98% Argon / Balance Oxygen

TYPICAL APPLICATION

- ER316LSi SS MIG wire is used for welding stainless steels, such as 316L and 316LN.

- Applied to Molybdenum bearing austenitic stainless steels, exceptionally performs at high wire feed speeds.

- Used in applications where a good cosmetic appearance is important.

WELDING POSITIONS

F,V,OH,H

WIRE COMPOSITION – As Required As per AWS A5.9/A5.9M

| Alloy Type | %C | %Cr | %Ni | %Mo | %Mn | %Si | %P | %S | %Cu | Other |

|---|---|---|---|---|---|---|---|---|---|---|

| ER316LSi | 0.03max | 18.0-20.0 | 11.0-14.0 | 2.0-3.0 | 1.0-2.5 | 0.65-1.00 | 0.03max | 0.03max | 0.75max | – |

| Typical Results | 0.014 | 19.2 | 12.7 | 2.4 | 1.7 | 0.76 | 0.013 | 0.012 | 0.49 | – |

DIAMETER

| INCH | 0.023” | 0.030” | 0.035” | 0.040” | 0.045” | 0.062” |

|---|---|---|---|---|---|---|

| MM | 0.6 | 0.8 | 0.9 | 1.0 | 1.2 | 1.6 |

Standard Package Dimensions and Weights

| Product | Spool Diameter(in) | Spool Diameter(mm) | Nomimal Weight(lbs) | Nominal Weight(kg) |

|---|---|---|---|---|

| Spools | 4 | 100 | 1-1/2, 2-1/2 | 0.7, 1.1 |

| 8 | 200 | 10 | 4.5 | |

| 12 | 300 | 25, 33 | 11.4, 15 | |

| 14 | 350 | 50 | 22.8 |

*Net weights shall be within ±10% of the nominal weight.

TYPICAL MECHANICAL PROPERTIES (As Welded)

| AWS No. | Tensile Strength, min(ksi) | Tensile Strength, min(MPa) | Elongation, min(%) | Heat Treatment |

|---|---|---|---|---|

| ER316LSi | 80 | 550 | 30 | None |

Available Diameters MIG with Operating Range in Amps

| Diameter(inch) | Diameter(mm) | Amps(A) |

|---|---|---|

| 0.023” | 0.6 | 35 – 70 |

| 0.030” | 0.8 | 50 – 100 |

| 0.035” | 0.9 | 100 – 150 |

| 0.045” | 1.2 | 150 – 200 |

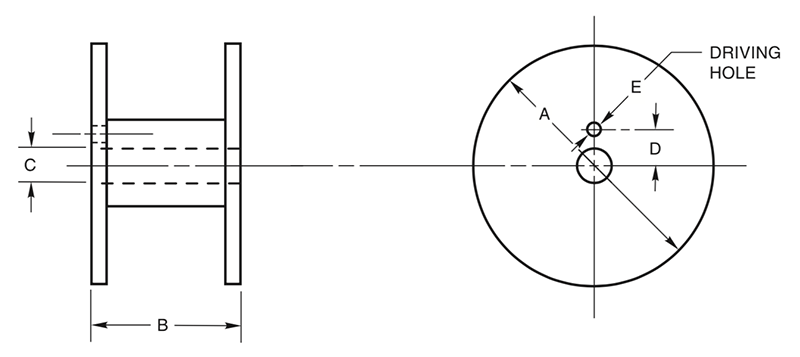

MIG SPOOL DIMENSIONS

| Dimensions of 4, 8 and 12 in [100, 200 and 300 mm] Standard Spools | |||||||||

| Type | Spools Details | 4 in [100mm] | 8 in [200mm] | 12 in [300mm] | 14 in [350mm] | ||||

| inch | mm | inch | mm | inch | mm | inch | mm | ||

| A | Diameter, max | 4.0 | 102 | 8.0 | 203 | 12 | 305 | 14 | 355 |

| B | Width Tolerance | 1.75 ±0.03 |

46 +0,-2 |

2.16 ±0.03 |

56 +0,-3 |

4.0 ±0.06 |

103 +0,-3 |

4.0 ±0.06 |

103 +0,-3 |

| C | Diameter Tolerance | 0.63 +0.01.-0 |

16 +1,-0 |

2.03 +0.06,-0 |

50.5 +2.5,-0 |

2.03 +0.06,-0 |

50.5 +2.5,-0 |

2.03 +0.06,-0 |

50.5 +2.5,-0 |

| D | Diameter between Axes Tolerance | — — |

— — |

1.75 ±0.02 |

44.5 ±0.5 |

1.75 ±0.02 |

44.5 ±0.5 |

1.75 ±0.02 |

44.5 ±0.5 |

| E | Diameter Tolerance | — — |

— — |

0.44 +0,-0.06 |

10 +1,-0 |

0.44 +0,-0.06 |

10 +1,-0 |

0.44 +0,-0.06 |

10 +1,-0 |