ER309 SS MIG WIRE | FEATURES

- The nominal composition (wt %) of ER309 is 24 Cr, 13 Ni, and the all-weld metal microstructure is normally austenite with a small amount of ferrite.

- It is used to weld Type 304 and similar base metals where severe corrosion conditions exist requiring higher alloy weld metal, such as 304, 304N, 305, 308 base metals.

- It is also used in dissimilar metal welds, such as joining Type 304 to carbon steel, welding the clad side of Type 304 clad steels, and applying stainless steel sheet linings to carbon steel shells.

- Suitable for applications at higher temperatures, and resistant to scaling up to 1830°F.

- Welding process of ER309 SS MIG wire applied to MIG(Metal Inert Gas Welding) or GMAW(Gas Metal Arc Welding).

SPECIFICATION CONFORMANCES

AWS: A5.9/A5.9M: ER309

UNS Number: S30980

BS EN ISO 14343A: 22 12 H

WELDING POSITIONS

F,V,OH,H

TYPICAL APPLICATION

- ER309 SS MIG wire is used for welding similar alloys in wrought or cast form.

- It is available as Batch Managed Inventory

- Power and process industry related piping

SHIELDING GAS

98% Argon+2% O2

WIRE COMPOSITION – As Required As per AWS A5.9/A5.9M

| Alloy Type | %C | %Cr | %Ni | %Mo | %Mn | %Si | %P | %S | %N | %Cu |

|---|---|---|---|---|---|---|---|---|---|---|

| ER309 | 0.12 | 23.0-25.0 | 12.0-14.0 | 0.75max | 1.0-2.5 | 0.30-0.65 | 0.03max | 0.03max | – | 0.75max |

| Typical Results | 0.032 | 23.2 | 12.8 | 0.52 | 1.8 | 0.51 | 0.013 | 0.015 | – | 0.46 |

DIAMETER

| INCH | 0.023” | 0.030” | 0.035” | 0.040” | 0.045” | 0.062” |

|---|---|---|---|---|---|---|

| MM | 0.6 | 0.8 | 0.9 | 1.0 | 1.2 | 1.6 |

Standard Package Dimensions and Weights

| Product | Spool Diameter(in) | Spool Diameter(mm) | Nomimal Weight(lbs) | Nominal Weight(kg) |

|---|---|---|---|---|

| Spools | 4 | 100 | 1-1/2, 2-1/2 | 0.7, 1.1 |

| 8 | 200 | 10 | 4.5 | |

| 12 | 300 | 25, 33 | 11.4, 15 | |

| 14 | 350 | 50 | 22.8 |

*Net weights shall be within ±10% of the nominal weight.

TYPICAL MECHANICAL PROPERTIES (As Welded)

| AWS No. | Tensile Strength, min(ksi) | Tensile Strength, min(MPa) | Elongation, min(%) | Heat Treatment |

|---|---|---|---|---|

| ER309 | 80 | 550 | 30 | None |

Available Diameters MIG with Operating Range in Amps

| Diameter(inch) | Diameter(mm) | Amps(A) |

|---|---|---|

| 0.023” | 0.6 | 35 – 70 |

| 0.030” | 0.8 | 50 – 100 |

| 0.035” | 0.9 | 160 – 210 |

| 0.045” | 1.2 | 180 – 250 |

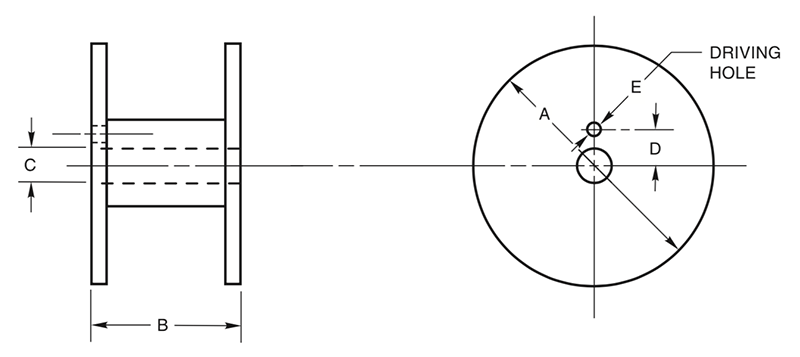

MIG SPOOL DIMENSIONS

| Dimensions of 4, 8 and 12 in [100, 200 and 300 mm] Standard Spools | |||||||||

| Type | Spools Details | 4 in [100mm] | 8 in [200mm] | 12 in [300mm] | 14 in [350mm] | ||||

| inch | mm | inch | mm | inch | mm | inch | mm | ||

| A | Diameter, max | 4.0 | 102 | 8.0 | 203 | 12 | 305 | 14 | 355 |

| B | Width Tolerance | 1.75 ±0.03 |

46 +0,-2 |

2.16 ±0.03 |

56 +0,-3 |

4.0 ±0.06 |

103 +0,-3 |

4.0 ±0.06 |

103 +0,-3 |

| C | Diameter Tolerance | 0.63 +0.01.-0 |

16 +1,-0 |

2.03 +0.06,-0 |

50.5 +2.5,-0 |

2.03 +0.06,-0 |

50.5 +2.5,-0 |

2.03 +0.06,-0 |

50.5 +2.5,-0 |

| D | Diameter between Axes Tolerance | — — |

— — |

1.75 ±0.02 |

44.5 ±0.5 |

1.75 ±0.02 |

44.5 ±0.5 |

1.75 ±0.02 |

44.5 ±0.5 |

| E | Diameter Tolerance | — — |

— — |

0.44 +0,-0.06 |

10 +1,-0 |

0.44 +0,-0.06 |

10 +1,-0 |

0.44 +0,-0.06 |

10 +1,-0 |