ER316L SS MIG WIRE | FEATURES

- ER316L is the same as ER316, except for the carbon content.

- Low carbon (0.03 percent maximum) in this filler metal reduces the possibility of intergranular chromium carbide precipitation and thereby increases the resistance to intergranular corrosion without the use of stabilizers such as niobium or titanium.

- The high carbon deposit provides creep strength and a high tensile strength at elevated temperatures.

- Welding process of ER316L SS MIG wire applied to MIG(Metal Inert Gas Welding) or GMAW(Gas Metal Arc Welding).

SPECIFICATION CONFORMANCES

AWS: A5.9/A5.9M: ER316L

UNS Number: S31683

BS EN ISO 14343B: SS316L

WELDING POSITIONS

F,V,OH,H

TYPICAL APPLICATION

- ER316L SS MIG wire is used for welding stainless steels, such as 316L and 316LN.

- This filler metal is primarily used for welding low-carbon molybdenum-bearing austenitic alloys. However, it is not as strong at elevated temperature as the niobium-stabilized alloys or Type ER316H.

- Applied to high pressure piping and tubing.

SHIELDING GAS

98% Argon+2% O2

WIRE COMPOSITION – As Required As per AWS A5.9/A5.9M

| Alloy Type | %C | %Cr | %Ni | %Mo | %Mn | %Si | %P | %S | %Cu | Other |

|---|---|---|---|---|---|---|---|---|---|---|

| ER316L | 0.03max | 18.0-20.0 | 11.0-14.0 | 2.0-3.0 | 1.0-2.5 | 0.30-0.65 | 0.03max | 0.03max | 0.75 | – |

| Typical Results | 0.016 | 19.3 | 12.2 | 2.43 | 1.7 | 0.47 | 0.013 | 0.016 | 0.43 | – |

DIAMETER

| INCH | 0.023” | 0.030” | 0.035” | 0.040” | 0.045” | 0.062” |

|---|---|---|---|---|---|---|

| MM | 0.6 | 0.8 | 0.9 | 1.0 | 1.2 | 1.6 |

Standard Package Dimensions and Weights

| Product | Spool Diameter(in) | Spool Diameter(mm) | Nomimal Weight(lbs) | Nominal Weight(kg) |

|---|---|---|---|---|

| Spools | 4 | 100 | 1-1/2, 2-1/2 | 0.7, 1.1 |

| 8 | 200 | 10 | 4.5 | |

| 12 | 300 | 25, 33 | 11.4, 15 | |

| 14 | 350 | 50 | 22.8 |

*Net weights shall be within ±10% of the nominal weight.

TYPICAL MECHANICAL PROPERTIES (As Welded)

| AWS No. | Tensile Strength, min(ksi) | Tensile Strength, min(MPa) | Elongation, min(%) | Heat Treatment |

|---|---|---|---|---|

| ER316L | 70 | 490 | 30 | None |

Available Diameters MIG with Operating Range in Amps

| Diameter(inch) | Diameter(mm) | Amps(A) |

|---|---|---|

| 0.023” | 0.6 | 35 – 70 |

| 0.030” | 0.8 | 50 – 100 |

| 0.035” | 0.9 | 160 – 210 |

| 0.045” | 1.2 | 180 – 250 |

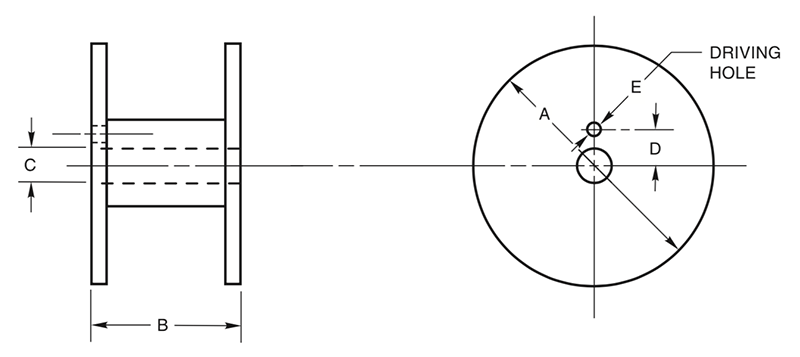

MIG SPOOL DIMENSIONS

| Dimensions of 4, 8 and 12 in [100, 200 and 300 mm] Standard Spools | |||||||||

| Type | Spools Details | 4 in [100mm] | 8 in [200mm] | 12 in [300mm] | 14 in [350mm] | ||||

| inch | mm | inch | mm | inch | mm | inch | mm | ||

| A | Diameter, max | 4.0 | 102 | 8.0 | 203 | 12 | 305 | 14 | 355 |

| B | Width Tolerance | 1.75 ±0.03 |

46 +0,-2 |

2.16 ±0.03 |

56 +0,-3 |

4.0 ±0.06 |

103 +0,-3 |

4.0 ±0.06 |

103 +0,-3 |

| C | Diameter Tolerance | 0.63 +0.01.-0 |

16 +1,-0 |

2.03 +0.06,-0 |

50.5 +2.5,-0 |

2.03 +0.06,-0 |

50.5 +2.5,-0 |

2.03 +0.06,-0 |

50.5 +2.5,-0 |

| D | Diameter between Axes Tolerance | — — |

— — |

1.75 ±0.02 |

44.5 ±0.5 |

1.75 ±0.02 |

44.5 ±0.5 |

1.75 ±0.02 |

44.5 ±0.5 |

| E | Diameter Tolerance | — — |

— — |

0.44 +0,-0.06 |

10 +1,-0 |

0.44 +0,-0.06 |

10 +1,-0 |

0.44 +0,-0.06 |

10 +1,-0 |