Radiography is one of the most popular non-destructive examination(NDE) methods for locating subsurface defects. It is used for examination of weldments in all types of materials: steel, aluminum, magnesium, and so on. Radiography is used in the pipeline industry to ensure proper weld quality.

Figure 1 Radiography Testing

Basic Principle of Radiographic Testing

Radiography is a nondestructive examination method that uses invisible. X-ray, or gamma radiation to examine the interior of materials. Radiographic testing (RT) gives a permanent film record of defects that is relatively easy to interpret. Although this is a slow and expensive method of nondestructive examination, it is a positive method for detecting porosity, inclusions, cracks, and voids in the interior of castings, welds, and other structures.

There are two different radioactive sources available for industrial use: X-ray and Gamma-ray. X-rays, generated by electron bombardment of tungsten, and gamma rays emitted by radioactive elements are penetrating radiation whose intensity is modified by passage through a material. The amount of energy absorbed by a material depends on its thickness and density. Thus a thinner part will absorb less energy than a thick part, and a heavy dense metal, such as steel, will absorb more energy than a light metal such as aluminum. Energy not absorbed by the material will cause exposure of the radiographic film. These areas will be dark when the film is developed. Areas of the film exposed to less energy remain lighter. Therefore, areas of the material where the thickness has been changed by discontinuities, such as porosity or cracks, will appear as dark outlines on the film. Inclusions of low density, such as slag, will appear as dark areas on the film, while inclusions of high density, such as tungsten, will appear as light areas. All discontinuities are detected by viewing shape and variations in the density of the processed film.

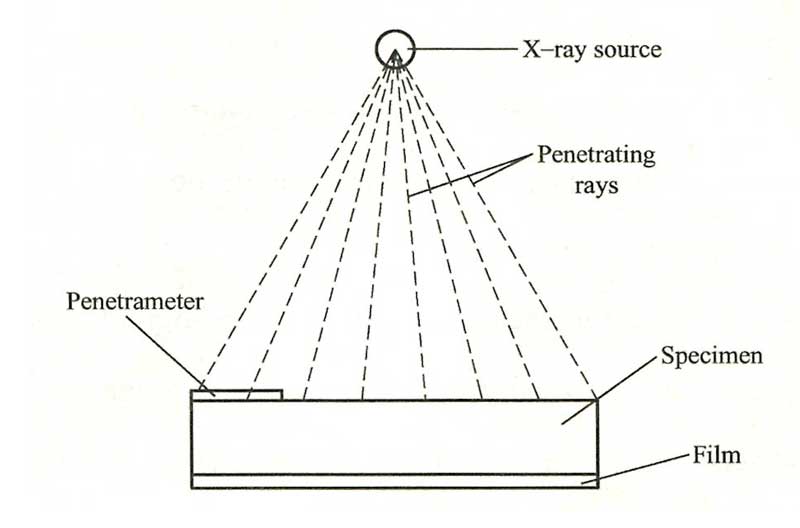

The X-ray or gamma-ray source and penetrameter are placed above the piece to be radiographed and the film is placed on the opposite side of the part (Figure 2).

Figure 2 Principle of Radiography Testing

X-ray and Gamma-ray of Radiographic Testing

X-rays are produced by electrons hitting a tungsten target inside an X-ray tube. In addition to the X-ray tube, the apparatus consists of a high-voltage generator with necessary controls. X-rays are produced when a high-speed stream of electrons collides with a piece of tungsten. The electrons are the anode by means of tungsten, and when the electrons hit it, X-rays are produced which are directed through a window to the part being inspected.

Gamma rays are produced by radioactive decay of certain radioisotopes. The radioisotopes normally used are cobalt-60, iridium-192, thulium-170, and cesium-137. These isotopes are contained in a lead or spent uranium vault or capsule to provide safe handling. They have a relatively short half-life and the strength of the radiation decreases with time.

Isotopes must be handled in such a way that radiographic sources can be positioned and yet produce minimum radiation hazards to operating personnel. Remote handling equipment is employed when the radioactive source is drawn from the shielded contained to the material to be radiographed. In the United States a license from the U.S. Department of Energy is required for use of radioisotopes.

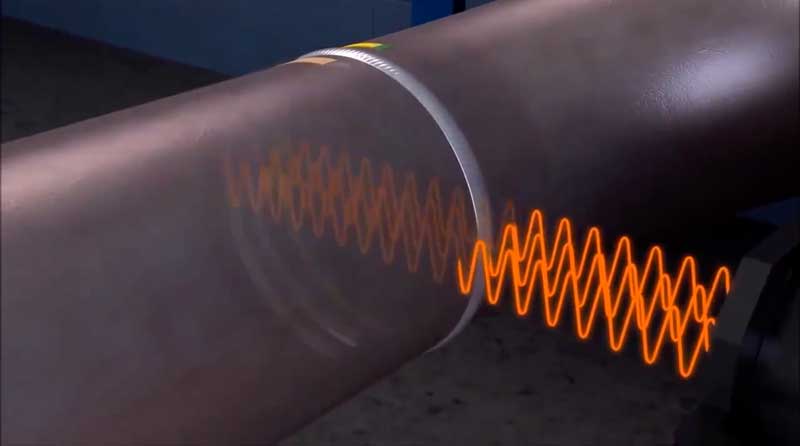

Figure 3 X-Ray Radiography of Welded Pipe

The radiation intensity or output from an X-ray machine or from radioisotope sources will vary. Common materials such as concrete and steel are used to house the X-ray machine and protect the operator from exposure. The thickness of the shielding enclosure walls should be sufficient to reduce exposure in all occupied areas to a minimum value. If the work is too large or too heavy to be brought into the shielded room, special precautions such as lead-lined booths and portable screens are used to protect personnel. In the field, radiography protection is usually obtained from distance alone, since radiation intensity decreases as distance increases.

Radiographic film of Radiographic Testing

Penetrameters are utilized to determine the level of sensitivity of the radiograph. They are made of the same material that is being examined and are usually 2% of the thickness of the part being checked. If the penetrameter can be seen clearly on the radiograph, any modification in thickness of the part (2% or more) will be seen clearly.

Radiographic movie consists of a transparent plastic sheet coated with a photographic emulsion. When X-rays strike the emulsion, an image is produced. The image is made visible and permanent by a movie processing operation. A lot of processing devices includes tanks that contain a designer, a fixer, and rinse solutions. Film processing operations are just as crucial as the movie direct exposure. Unsatisfactory radiographs can in some cases be credited to errors in the processing method or from mishandling of products.

Many indications will show up as dark areas against the light background of the sound weld. Radiographs should be analyzed with a movie illuminator providing a strong light.

It is vital that qualified personnel carry out X-ray analyses since incorrect interpretation of radiographs causes a loss of time and money. Radiographs for recommendation are incredibly practical in protecting right interpretations. Consulting the requirements included for requirements of acceptability and credentials of devices and operators.

Inspection of welding of Radiographic Testing

The beam of radiation must be directed to the middle of the area under examination and need to be normal to the product surface at that point, other than in unique techniques where known defects are best revealed by a different alignment of the beam. The length of weld under examination for each exposure will be such that the density of the material at the diagnostic extremities, measured in the direction of the incident beam, does not go beyond the real density at that point by more than 6%. The specimen to be inspected is put in between the source of radiation and the finding gadget, typically the film in a light tight holder or cassette, and the radiation is allowed to penetrate the part for the required length of time to be sufficiently tape-recorded.

The result is a two-dimensional projection of the part onto the film, producing a latent image of varying densities according to the quantity of radiation reaching each location. Since movie is cumulative in its action (the direct exposure increasing as it absorbs more radiation), relatively weak radiation can be detected by lengthening the direct exposure up until the film can tape-record an image that will be noticeable after development.

Before beginning a radiographic evaluation, it is constantly a good idea to examine the element with one’s own eyes, to get rid of any possible external problems. If the surface of a weld is too irregular, it may be desirable to grind it to get a smooth finish, however this is likely to be limited to those cases in which the surface abnormalities (which will be visible on the radio chart) might make finding internal flaws tough.

After this visual examination, the operator will have a clear concept of the possibilities of access to the two faces of the weld, which is necessary both for the establishing of the devices and for the choice of the most appropriate technique.

Flaws such as delaminations and planar cracks are hard to spot using radiography, particularly to the untrained eye.

Without ignoring the negatives of radiographic examination, Radiography does hold many significant advantages over ultrasonics, particularly insomuch that as a ‘picture’ is produced keeping a semi irreversible record for the life cycle of the movie, more precise identification of the defect can be made, and by more interpreters. Extremely essential as most building and construction requirements permit some level of problem acceptance, depending upon the type and size of the flaw.

Picture Source:

Get Notified of New Articles

Leave your email to get our weekly newsletter.