Most of the CO2 gas shielded welding is manual welding with a hand-held welding torch, commonly known as “semi-automatic” welding. Sometimes roller frames and small rail cars can be used to achieve full-automatic welding of cylindrical and flat butt joints.

1.Advantages of CO2 gas shielded welding

The reason why CO2 gas shielded welding can be quickly promoted in a short time is mainly because it has the following advantages:

1) Production efficiency is greatly improved

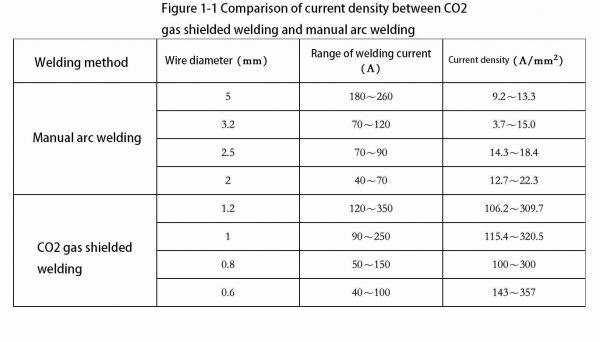

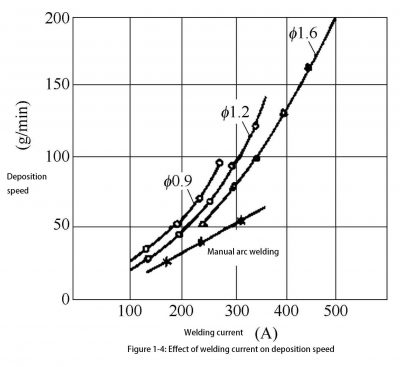

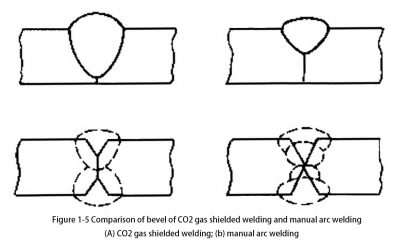

(1) The current density of CO2 gas shielded welding is much larger than that of manual arc welding, see Table 11. It can be seen from Table 11 that the current density used for CO2 gas shielded welding is usually 100-300A / mm2, the welding wire has a high deposition speed (Figure 14), and the base metal has a large penetration depth. For steel plates below 10mm, an I-shape can be opened. The bevel is welded through once. For thick plates, the blunt edge can be enlarged and the bevel can be reduced to reduce the metal filling and improve the welding efficiency, as shown in Figure 15.

(3) CO2 gas shielded welding adopts a whole set of welding wire (Figure 16). There is no need to change the welding wire during the welding process, so the time for replacing the welding rod during arc stop is reduced, which saves the filler metal (no loss of the electrode head) and reduces the lead. The number of arcings has greatly reduced the possibility of welding defects due to arc stop.

2) Not sensitive to oil rust. Because CO2 gas is decomposed during the CO2 gas shielded welding process, it is extremely oxidizing, and its sensitivity to oil, rust and other dirt on the workpiece is greatly reduced. The cleaning requirements are not very high. As long as there is no obvious yellow rust on the workpiece, it is generally not necessary to remove it.

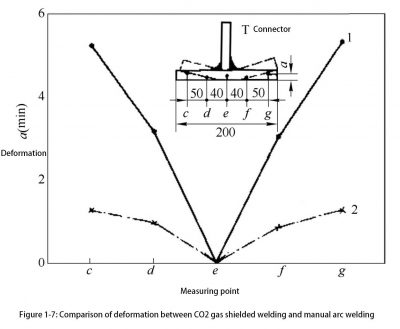

3) Small welding deformation Because of the high current density of CO2 gas shielded welding, the concentration of arc heat, and the cooling effect of CO2 gas, the heated area is relatively small, so the deformation of the workpiece after welding is small, as shown in Figure 17, especially It can reduce the workload of correcting deformation when welding thin plates.

5) The use of open-arc welding CO2 gas shielded welding has good visibility of the arc, and it is easy to accurately align the welding seam for welding. It is more convenient to observe and control the welding process.

6) Simple operation: CO2 gas shielded welding uses an automatic wire feeding mechanism, which is easy to operate and easy to master. Based on the manual arc welding operation technology, CO2 gas shielded welding can be performed after short-term training.

7) Low welding cost: The source of CO2 gas is relatively wide, the price is relatively low, and the power consumption during the welding process is also small. The welding cost is 40% to 50% of manual arc welding.

2. Disadvantages of CO2 gas shielded welding

1) Spattering during welding. If the CO gas generated during welding appears in the droplets, the droplets in the transition to the welding pool will explode due to the expansion of the gas, forming a metal splash during welding.

2) Alloy elements are easily burned during the welding process. The CO2 gas and O2 decomposed at high temperature have strong oxidizing properties, and their oxidizing properties are continuously strengthened as the temperature increases. During the welding process, strong oxidation The characteristics will lead to the burning of alloying elements.

3) Weak wind resistance of the gas protection zone during welding. During CO2 gas shielded welding, due to the protective effect of CO2 gas flow, the air around the welding arc zone is exhausted out of the welding arc zone to protect the electrodes and molten metal that are good at high temperatures. And the metal near the seam area in the high temperature area, so that these locations do not contact the surrounding air, to prevent oxidation by O2 in the air. However, if the protective effect of CO2 gas is damaged by natural wind during welding, the quality of the weld of CO2 gas shielded welding will be deteriorated. Therefore, when outdoor welding is performed, wind protection measures must be taken around the CO2 gas shielded welding.

4) The wire-type welding torch is heavier than the manual arc welding tongs. CO2 gas shielded welding wire-type welding torch has wire wire and wire feeding motor, as shown in Figure 18. Although the power of the wire feeding motor is small (usually about 10W) and the weight of the wire reel is not more than 1kg, the entire welding torch is much heavier than the manual arc welding tongs, thus increasing the labor intensity during the welding operation, and in a small range The operation inside is even more inconvenient and inflexible.

5) The welding equipment is more complicated. The CO2 gas shielded welding machine is mainly composed of 7 parts: welding power source, control box, wire feeding mechanism, welding gun (manual welding torch or automatic welding trolley), CO2 gas supply device, remote control. Box, cooling water circulation device (cooling torch for high current welding), etc. The composition of its equipment is more complicated than that of electrode arc welding machines. When welding on a welding site that needs to be moved frequently, there is no maneuverability of electrode arc welding.

Get Notified of New Articles

Leave your email to get our weekly newsletter.