First, CO2 gas shielded welding arc

1. Arc static characteristics

When the length of the arc does not change during welding, the arc can burn stably. The relationship between the voltage and current at both ends of the arc is called the static characteristic of the arc. Because the current density used for CO2 gas shielded welding is very large, the static characteristics of the arc are in the rising stage, that is, the arc voltage increases when the welding current increases.

2. Arc polarity

Under normal circumstances, CO2 gas shielded welding uses DC reverse connection. When the DC reverse connection is adopted, the welding current is relatively stable, the metal splash is small, the forming is also good, the penetration depth is large, and the content of diffusible hydrogen in the weld metal is small. However, DC surfacing is more suitable when surfacing welding and repair welding of cast iron, because during welding, the calorific value of the cathode is greater than the calorific value of the anode. When the positive polarity is connected to the cathode, the melting coefficient is large, which is about 1.6 of the reverse polarity. Times, the penetration depth is shallow, and the dilution rate of the surfacing metal is also small, which is beneficial to the implementation effect of welding.

Second, the droplet transfer of CO2 gas shielded welding

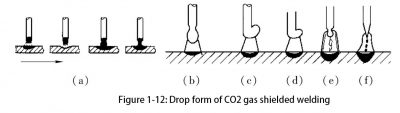

In the process of CO2 gas shielded welding, the stability of arc combustion and the formation of welds depend on the droplet transfer form. In addition, the droplet transfer also affects the welding process and metallurgical characteristics. Select reasonable welding process parameters to obtain the desired droplet transfer form, thereby ensuring stability during welding and reducing spatter. The forms of droplet transfer of CO2 gas shielded welding can be roughly divided into three types of short-circuit transition, particle transition and semi-short-circuit transition, as shown in Figure 1-12.

1. Short-circuit transition

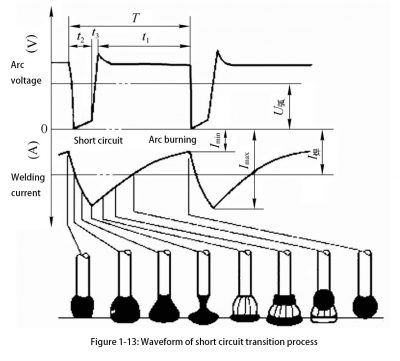

In the process of CO2 gas shielded welding, if the welding current is too small, the welding arc is unstable, and the welding wire droplet is mainly affected by gravity to show a large droplet transition. Not only the molten droplet transition is weak, but the formation of the weld is not very good. At this time, if the arc voltage is reduced to make the arc length of the welding arc smaller than the diameter of the droplet when the droplet is freely formed, not only the welding arc is stable and the welding spatter is small, but the frequency of the transition from the droplet to the welding pool is also increased. Greatly improved. This small welding current and low arc voltage welding method is a droplet short-circuit transition, which is widely used for welding thin plates and space locations. Figure 1-13 shows the welding current and arc voltage waveforms during the short-circuit transition.

During the short-circuit transition of the droplet, the droplet at the end of the welding wire continuously grows in the arc, the short-circuit contact between the droplet and the undulating molten pool, and a short-circuit liquid bridge is established between the end of the welding wire and the welding molten pool. It will be affected by gravity, internal viscous force, surface tension, electromagnetic contraction force caused by short-circuit current, and gas blast force, etc., to realize the short-circuit transition of the droplet.

In order to obtain the highest short-circuit frequency, the most suitable arc voltage should be selected. For a welding wire with a diameter of 0.8 to 1.2 mm, the value is about 20V, and the maximum short-circuit frequency is about 100 Hz. When short-circuit transition welding is used, a uniform “snap” sound can be heard because the arc is constantly short-circuited. If the arc voltage is too low, because the arc length is very short, the frequency of the short circuit is very high, and the arc burns for a short time, it may be inserted into the molten pool before the welded ends have time to melt, and a solid short circuit will occur, due to the large current of the short circuit. As a result, the welding wire burst suddenly, causing serious splashes and making the welding process extremely unstable. At this time, you can see that many short sections of welding wire are inserted in the weld, like a hedgehog.

2. Particle transition

When the welding current is large and the arc voltage is high, particle transitions will occur. The effect of welding current on the particle transition is very significant. As the welding current increases, the droplet volume decreases and the transition frequency increases. There are three situations:

1) Particle transition When the upper limit of welding current and short-circuit current are similar, but the arc voltage is higher, the arc is longer, the droplet will not be short-circuited when it grows to the maximum, and it will fall into the molten pool under the effect of gravity. In this case, the welding process is stable. The splash is small, and it is often used to weld thin plates.

2) Large particle transition When the welding current is larger than the short-circuit current and the arc voltage is high, because the welding wire melts faster, a large molten droplet appears at the end, not only swinging left and right, but also jumping up and down, and a part of it becomes a large particle splash. Part of it falls into the molten pool, this transition form is called large particle transition. There are many spatters during the transition of large particles, the weld formation is not very good, the welding process is unstable, and it has no application value.

3) Fine particle transition: When the welding current further increases, the droplets become thinner and the transition frequency is higher. At this time, there is less spatter and the welding process is stable. It is called fine particle transition (also called small particle transition). For φ1.6mm welding wire, when the welding current exceeds 400A, it is a transition of fine particles, less spatter, stable welding process, high welding wire melting efficiency, suitable for welding medium and thick plates. During the transition of fine particles, the droplets at the end of the wire are small and swing left and right.

3. Half short circuit transition

A short-circuit transition occurs when the welding current is low and the arc voltage is low, and a fine-grain transition occurs when the welding current is high and the arc voltage is high; if the welding current and arc voltage are in the middle of the above two conditions, a semi-short-circuit transition occurs, such as For a φ1.2mm welding wire, when the welding current is 180 ~ 260A and the arc voltage is 24 ~ 31V, a semi-short-circuit transition can occur. At this time, in addition to a small number of large particles falling into the molten pool, a semi-short-circuit transition will also occur.

The shape of the weld is better during semi-short-circuit transition, but the spatter is large. When the characteristics of the welder are suitable, the spatter loss can be reduced to a few percent. Semi-short-circuit transition is suitable for welding of 6-8mm medium-thickness steel plates.