An electric welding electrode is a melting electrode for hand arc welding with a suitable thickness of a coating on the surface of a metal wire, that is, a core. The electrode is composed of two parts: a welding core and a coating. Welding core refers to the metal core covered by the coating for the electrode, such as H08A steel core. The welding core has two functions: one is to conduct current and generate a welding arc; the other is to melt the core itself to form the filler metal in the weld. Because the welding core melts under the action of the high temperature of the arc and forms a droplet to transfer to the molten pool, the chemical composition of the welding core has a great influence on the structure and properties of the weld metal. Electrode coating refers to a coating layer that is covered on the surface of the core by fine particles with different physical and chemical properties. The main function of the electrode cover is threefold:

①Mechanical protection: During welding, a large amount of gas is generated after the electrode coating is melted to cover the arc area and the molten pool, which basically isolates the molten metal from the air. These gases can form a good protective layer around the arc area and the molten pool, prevent the intrusion of oxygen and nitrogen in the air, and play a role in protecting the molten metal. During the welding process, the coating is melted by the arc at high temperature to form slag covering the droplets and the molten pool metal. This not only isolates the oxygen and nitrogen in the air, protects the weld metal, but also slows down the cooling rate of the weld and promotes the weld metal. The exhaust of medium gas can reduce the possibility of generating pores, and can improve the formation and crystallization of the weld, and play a role of slag protection.

② Metallurgical effect: Through the metallurgical reaction of slag and molten metal, harmful impurities (such as oxygen, hydrogen, sulfur, and phosphorus) are removed, and beneficial alloying elements are added, so that the weld can obtain the required mechanical properties. Due to the high temperature of the arc, some alloying elements contained in the weld metal are burned (oxidized or nitrided), which will reduce the mechanical properties of the weld. By adding iron alloy or pure alloy elements to the electrode coating, it will be transferred to the weld metal as the coating melts, so as to compensate for the alloy element burnout and improve the mechanical properties of the weld metal.

③Improve welding process performance: Stable arc burning, less spatter, good weld formation, easy slag removal and high deposition efficiency.

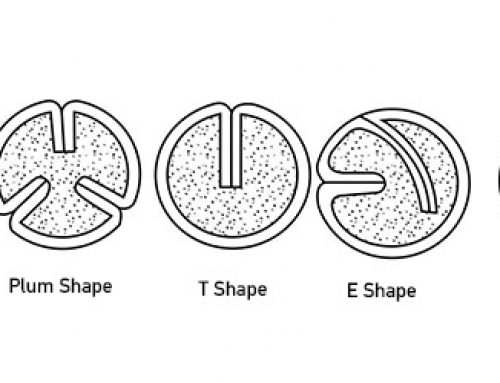

The electrode cover is composed of a variety of raw materials, and the type of the electrode cover can be determined according to the main components of the cover. For example, ilmenite is the main type of ilmenite in the skin; when the skin contains more than 30% of titanium dioxide and less than 20% of calcium and magnesium carbonate, it becomes titanium-calcium. The only exception is the low-hydrogen type. Although its skin is mainly composed of calcium, magnesium carbonate and fluorite, it is named after the lowest hydrogen content in the weld as its main feature. For some skin types, because the adhesives used are potassium water glass and sodium water glass, the same skin type is further divided into potassium and sodium types, such as low-hydrogen potassium type and low-hydrogen sodium type. The former can be used for AC and DC welding power, while the latter can only use DC power.