There are many ways to classify the welding wire. The welding wire can be classified from different angles according to the applicable welding method, the material to be welded, the manufacturing method and the shape of the welding wire:

①According to its applicable welding method, it can be divided into submerged arc automatic welding wire, electroslag welding wire, CO2 welding wire, surfacing welding wire, gas welding wire, etc. There are two types of welding wire used in submerged arc welding: solid welding wire and flux-cored welding wire. Solid welding wire is commonly used in production. Flux-cored welding wire is only used in some special occasions. Flux-cored welding wire has been widely used in CO2 gas shielded welding.

②According to different metal materials to be welded, it can be divided into carbon structural steel welding wire, low alloy steel welding wire, stainless steel welding wire, nickel-based alloy welding wire, cast iron welding wire, non-ferrous metal welding wire and special alloy welding wire.

③According to the manufacturing method and the shape of the welding wire, it can be divided into two categories: solid core welding wire and flux cored welding wire. Among them, flux-cored welding wire can be divided into two types: gas shielded welding wire or self-shielded welding wire. At present, it is more commonly used to classify according to the manufacturing method and its applicable welding method.

how is flux cored wire different from solid welding wire?

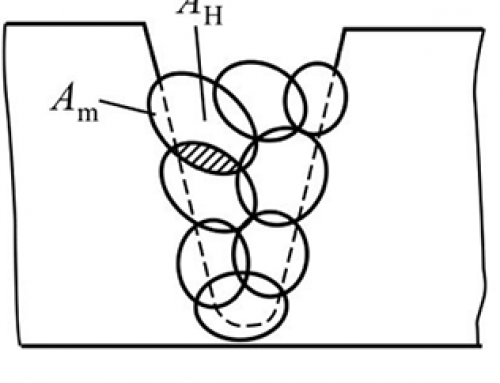

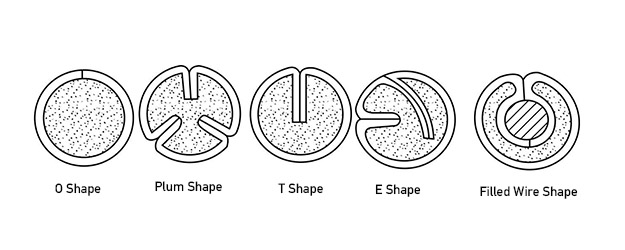

The solid wire is made of hot-rolled wire by drawing, generally called welding wire. It is widely used in various automatic and semi-automatic welding processes. Carbon steel and low alloy steel wire rods with large output and low alloy element content are often smelted in a converter; wire rods with small output and high alloy element content are mostly smelted in an electric furnace, which are formed by opening and rolling. There are many types of solid wire, which can be selected according to the material and welding method of the welding structure. Flux-cored welding wire is a welding wire formed by rolling a thin steel strip into a round steel tube or a special-shaped steel tube, filling with a certain amount of powder and drawing it. Flux-cored wire can be used alone or with flux or shielding gas. The cross-sectional shape of the flux-cored wire has a great influence on the welding process performance and metallurgical performance. The cross-sectional shape of the commonly used flux-cored wire is shown in Figure below.

Cross-sectional shape of commonly used flux-cored wire

The arc of the O-shaped welding wire is generated along the O-shaped steel skin at the end of the wire, and drifts indefinitely, and even a rotating arc is formed along the steel skin, causing a large splash. The cores often fall in pieces, so the metallurgical reaction is also unstable. The arcs of E-type and intermediate-wire-filled flux-cored wires can be stably burned on the entire end face of the wire, and the protection effect is better.