Self-shielded welding wire refers to welding wire that can be used for arc welding without the need for external protective gas or flux. The self-protected flux-cored wire puts the powder and metal powder as slag, gas, and deoxidation into the steel skin. During welding, the powder becomes slag and gas under the action of the arc, which plays a protective role in slag and gas Without additional gas protection. As some powders in the core are vaporized and decomposed during welding, some gas is released, forming a protective barrier to isolate the air, while containing a certain amount of deoxidizers (such as Al, Ti, Si, Mg, etc.) and strong nitrides Elements (such as Al, Ti, etc.) can prevent the occurrence of pores in the weld and reduce the impact toughness of the weld metal due to the high nitrogen content. The high aluminum content in the weld metal is a characteristic of self-shielded flux-cored wire. In order to avoid the formation of CO and N2 pores in the weld, as a strong deoxidizer and a strong nitride forming element, it is necessary to add Al. The slag system of self-protected flux-cored wire is significantly different from other welding materials. In order to prevent the harmful effects of the atmosphere on the welding process, a large amount of fluoride is used as self-protected flux-cored wire for gas production and slag formation, and strong deoxidizer and denitrifier Al are used to deoxidize and denitrify. In the selection of gas and slag forming agents, a variety of fluorides are often used in self-shielded flux-cored welding wires, such as BaF2, NaF, CaF2, SrF2, etc.

Self-protected flux-cored welding wire is suitable for downward welding, field or high-altitude operations in pipeline construction because it does not require shielding gas, and has high production efficiency, especially in high-rise buildings, oil and gas pipelines, installation sites and construction sites, offshore platforms, etc. Various outdoor construction sites are more widely used. It has the following obvious advantages: the self-protected flux-cored wire arc welding method does not require an additional protective gas source, the welding gun has a simple structure, light weight, easy operation, and strong construction flexibility; the deposition efficiency of the self-protected flux-cored wire is significantly higher than The welding rod is high, and the flexibility and wind resistance of field welding are better than other gas-shielded welding. It can usually be welded smoothly under the four-level wind; the rust resistance is excellent, the requirements for assembly size are not high, and it can be welded in all positions; The plasticity and toughness of the weld metal of the protective welding wire is generally lower than that of the flux-cored welding wire with auxiliary protective gas.

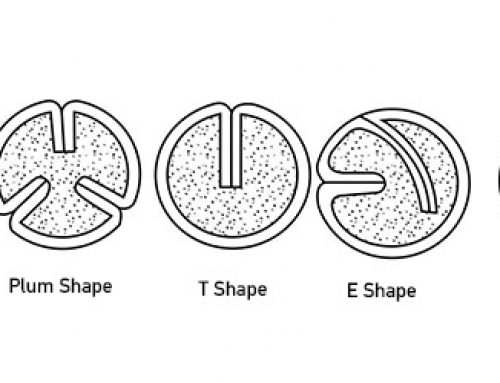

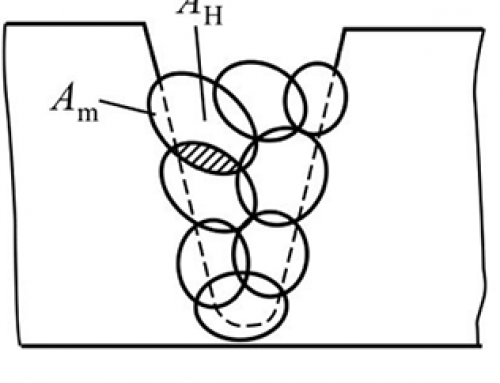

The shortcomings of the self-protected flux-cored wire are that the adaptability of the process parameters is small, the operation processability and the mechanical properties of the joint are difficult to unify. This is due to its low structure and low filling volume of the core, with the core inside and the steel skin outside, which results in insufficient protection of the droplets and molten pool. Compared with the gas-shielded flux-cored wire, the self-shielded flux-cored wire has a large splash and a large amount of smoke, so pay attention to strengthen ventilation when working in a narrow space.