According to the room temperature organization, stainless steel can be classified into four categories: austenitic stainless steel, martensitic stainless steel, ferritic stainless steel, and austenitic + ferritic duplex steel. Austenitic stainless steel contains 14% to 25% Cr, and Ni8% to 25%. The series represented by Cr18Ni8 are mainly used for corrosion resistance, and the series represented by Cr25Ni20 are mainly used for high temperature resistance.

When selecting austenitic stainless steel welding materials, we must first ensure that the weld metal has the same corrosion resistance as the base metal, that is, the main chemical composition of the weld metal should be as close as possible to the base metal, and secondly, the weld must have good crack resistance. And comprehensive mechanical properties.

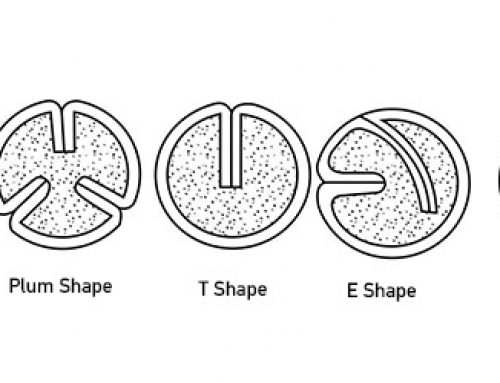

Cr1 series and Cr12-based multi-alloyed steels are martensitic stainless steels, and these steels have a large tendency to harden. The main problems that occur when welding martensitic stainless steel are cold cracks and hardening and embrittlement near the seam. There are two ways to choose martensitic stainless steel welding materials: First, in order to meet the performance requirements, the chemical composition of the weld metal and the base metal should be consistent, so that the mechanical properties and use properties of the two after heat treatment (such as corrosion resistance) Similar), in which case a homogeneous filling material must be used. Second, in the case where preheating or post-weld heat treatment cannot be used, in order to prevent cracks, an austenitic welding material is used to make the weld seam into an austenite structure. In this case, the weld strength is difficult to match with the base metal.

High chromium steels containing 17% to 28% Cr are ferritic stainless steels and are mainly used as heat stable steels. Ferritic stainless steel does not undergo phase transformation during welding heating and cooling, and even after rapid cooling after welding, no hardened structure is produced. The problem that occurs when welding ferritic stainless steel is that the grains in the near seam area tend to grow, forming coarse ferrite, and the toughness of the heat affected zone decreases, resulting in embrittlement. For ferritic stainless steel welding, a welding material with a low content of impurities (C, N, S, P, etc.) should be selected, and the welds should be alloyed reasonably to improve their weldability and toughness. According to the performance requirements of welded joints, the welding consumables used in ferritic stainless steel welding can be high-chromium ferrite electrodes or wires with similar composition to the parent metal, or chromium-nickel austenite electrodes or wires. When using austenitic welding consumables, no pre-heating or post-weld heat treatment is performed. The selection of common stainless steel electrodes is shown in Table below.