Gas tungsten arc welding(GTAW) is the most versatile of the welding processes. It can be used on any material, it produces the cleanest and best penetrating welds, and it allows you much more control over how the weld lays down. With GTAW, you have the option of slowing down, using less filler, and working the puddle to achieve the look and size weld you need.

Basic of GTAW

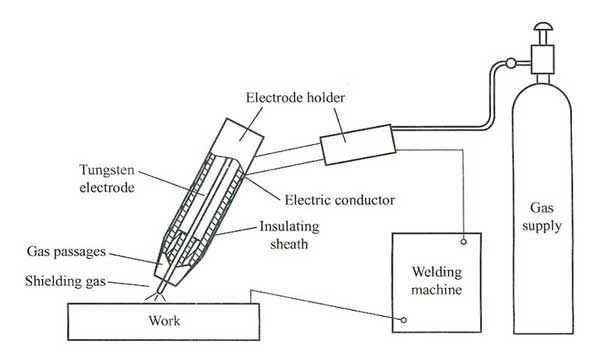

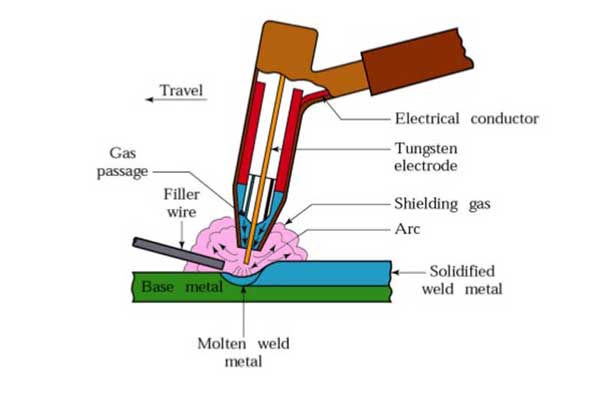

In the gas tungsten arc welding process (GTAW), a virtually non-consumable tungsten electrode is used to provide the arc for welding. During the welding cycle a shield of inert gas expels the air from the welding area and prevents oxidation of the electrode, weld puddle, and surrounding heat-affected zone (Figure 1).

Figure 1 Schematic diagram of gas tungsten arc welding equipment

In GTAW, the electrode is used only to create the arc. It is not consumed in the weld. In this way it differs from the regular shielded metal arc welding process, where the stick electrode is consumed in the weld. For joints where additional weld metal is needed, a filler rod is fed into the puddle in a manner similar to the oxy- acetylene welding.

Current for GTAW

Any standard DC or AC arc welding machine can be used to supply the current for GTAW. The choice of an AC or DC machine depends on weld characteristics that may be required. Some metals are joined more easily with AC current while with others better results are obtained when DC current is used.

With direct current the welding circuit may be either straight or reverse polarity. When the machine is set for straight polarity the flow of electrons from the electrode to the plate exerts considerable heat on the plate. In reverse polarity, the flow of electrons is from the plate to the electrode, thus causing a greater concentration of heat at the electrode.

The intense heat at the electrode tends to melt off the end of the electrode and contaminate the weld. Hence, for any given current DCRP requires a larger diameter electrode than DCSP. For example, a 1/16’’ diameter tungsten electrode normally can handle about 125 amperes in a straight-polarity circuit. However, if reverse polarity is used with this amount of current the tip of the electrode would melt off. Consequently a 174 diameter electrode would be required to handle 125 amperes of welding current.

Polarity also affects the shape of the weld. DCSP produces a narrow deep weld whereas DCRP with its larger diameter electrode and lower current forms a wide and shallow weld. For this reason DCRP is never used in gas tungsten arc welding except in rare occasions for welding aluminum and magnesium.

Direct current straight polarity is used for welding most metals because better welds are achieved. With the heat concentrated at the plate the welding process is more rapid, there is less distortion of the base metal, and the weld puddle is deeper and narrower than with DCRP. Since more heat is liberated at the puddle, smaller diameter electrodes can be used.

AC welding is actually a combination of DCSP and DCRP. An AC machine must be equipped with a high frequency generator to supply an even current. Remember that in an AC welder, the current is constantly reversing its direction. Every time the current flow changes direction, there is a very short interval when no current is flowing. These cause the arc to be unstable, and sometimes go out. With a high frequency generator in the system a more even current flow is possible. This stabilizes the arc.

Shielding Gas for GTAW

Shielding gas for gas tungsten arc welding can be argon, helium, or a mixture of argon and helium. Argon is used more extensively because it is less expensive than helium. Argon is 1.4 times as heavy as air and 10 times as heavy as helium. There is very little difference between the viscosity of these two gases. Since argon is heavier than air it provides a better blanket over the weld. Moreover, there is less clouding during the welding process with argon and consequently it permits better control of the weld puddle and arc.

Gas Tungsten Arc Welding

Argon normally produces a better cleaning action especially in welding aluminum and magnesium with alternating current. With argon there is a smoother and quieter arc action. The lower arc voltage characteristic of argon is particularly advantageous in welding thin material because there is less tendency for burning through the metal. Consequently, argon is used most generally for shielding purposes when welding materials up to 1/8” in thickness both for manual welding and low speed machine welding.

The use of argon also permits better control of the arc in vertical and overhead welding. As a rule, the arc is easier to start in argon than in helium and for a given welding speed the weld produced is narrower with a smaller heat-affected zone.

Material of GTAW

Gas Tungsten Arc Welding is most commonly used to weld stainless steel and nonferrous materials. It can be applied to nearly all metals. Furthermore, GTAW can be performed in a variety of other-than-flat positions, depending on the skill of the welder and the materials being welded.

For GTAW of stainless steels, the selection of a filler material is important to prevent excessive porosity. Oxides on the filler material and workpieces must be removed before welding to prevent contamination, and immediately prior to welding, alcohol or acetone should be used to clean the surface. Commonly used Stainless Steel TIG welding wire for GTAW could be 308 TIG rod, 309 TIG rod, 316 TIG rod. Austenitic stainless steels do not require preheating, but martensitic and ferritic chromium stainless steels should be preheating. Pure argon is used for thin workpieces, but helium can be introduced as thickness increases.

Stainless Steel TIG Welding Rod

Advantages of GTAW

The greatest advantage of the GTAW process is that it will weld more kinds of metals and metal alloys than any other arc welding process. GTAW can be used to weld most steels including stainless steel, nickel alloys such as Monel and Inconel, titanium, aluminum, magnesium, copper, brass, bronze, and even gold. GTAW can also weld dissimilar metals to one another such as copper to brass and stainless to mild steel. The advantages of GTAW process are as follows:

Concentrated Arc: The concentrated nature of the GTAW arc permits pin-point control of heat input to the workpiece resulting in a narrow heat-affected zone. A high concentration of heat is an advantage when welding metals with high heat conductivity such as aluminum and copper. A narrow heat-affected zone is an advantage because this is where the base metal has undergone a change due to the superheating of the arc and fast cooling rate. The heat-affected zone is where the welded joint is weakest and is the area along the edge of a properly made weld that would be expected to break under a destructive test.

No Slag: There is no requirement for flux with this process; therefore, there is no slag to obscure the welder’s vision of the molten weld pool. The finished weld will not have slag to remove between passes. Entrapment of slag in multiple pass welds is seldom seen. On occasion with materials like Inconel this may present a concern.

No Sparks, Spatter, or Noise: In GTAW process there is no transfer of metal across the arc. There are no molten globules of spatter to contend with and no sparks produced if the material being welded is free of contaminants. Also under normal conditions the GTAW arc is quiet without the usual cracks, pops, and buzzing of shielded metal arc welding and gas metal arc welding. Generally, the only time noise will be a factor is when a pulsed arc, or AC welding mode is being used.

No Smoke or Fumes: The process itself does not produce smoke or injurious fumes. If the base metal contains coatings or elements such as lead, zinc, nickel or copper that produce fumes, these must be contended with as in any fusion welding process on these materials. If the base metal contains oil, grease, paint or other contaminants, smoke and fumes will definitely be produced as the heat of the arc bums them away. The base material should be cleaned to make the conditions most desirable.

Disadvantages of GTAW

The main disadvantage of the GTAW process is the low filler metal deposition rate. Another disadvantage is that the hand-eye coordination necessary to accomplish the weld is difficult to learn, and requires a great deal of practice to become proficient. The arc rays produced by the process tend to be brighter than those produced by SMAW and GMAW. This is primarily due to the absence of visible fumes and smoke. The increased amounts of ultraviolet rays from the arc also cause the formation of ozone and nitrous oxides.Care should be taken to protect skin with the proper clothing and protect eyes with the correct shade lens in the welding hood. When welding in confined areas, concentrations of shielding gas may build up and displace oxygen. Make sure that these areas are ventilated properly.

Get Notified of New Articles

Leave your email to get our weekly newsletter.